Our Product Quality Assurance Standards

RB Royal goes to great lengths to ensure quality parts are delivered time after time. As an ISO Certified company since 1999, we understand total quality management and the importance it plays with your offering to your customers. Supporting the process, we document and verify all ECRs, conduct internal testing/verification, and maintain a system of third party verification of all fixtures. Our fully equipped on-site testing lab is equipped to check virtually every detail from dimensions to cleanliness testing. In addition to offering full PPAP and FAI, we also can coordinate off-site, third-party testing, and verification as required.

Quality-Environmental Policy

RB Royal Industries (RBR) is committed to customer satisfaction and managing the impact that our operations may have on the environment.

RBR honors this commitment by integrating safety, environmental and quality controls into our daily activities. The RBR Management team conducts regular reviews of the established objectives and monitors the implementation of actions that improve overall performance.

RBR strives to:

- Develop relationships to better understand and meet all expectations, become customer and supplier of choice by using data, employee and customer feedback in order to drive continuous improvement.

- Conduct business that promotes employee safety and wellbeing, environmental stewardship, meets all compliance obligations, minimizes the consumption of natural resources and prevents pollution.

By adhering to this policy, the employees of RBR believe that we sustaining the viability of our business and providing greater value for our interested parties.

This policy will be communicated to all RBR employees and will be made available to the public.

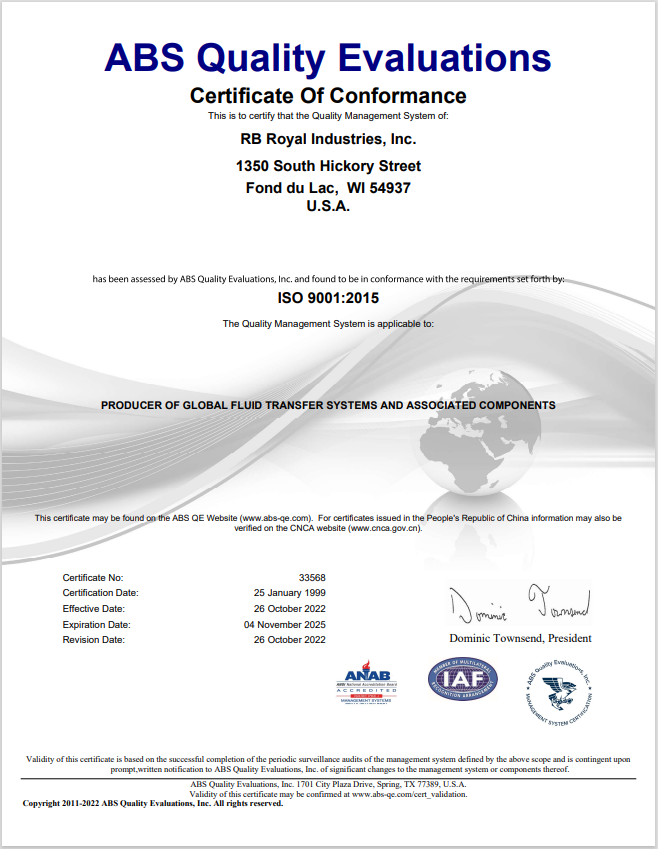

ISO 9001:2015 Certification:

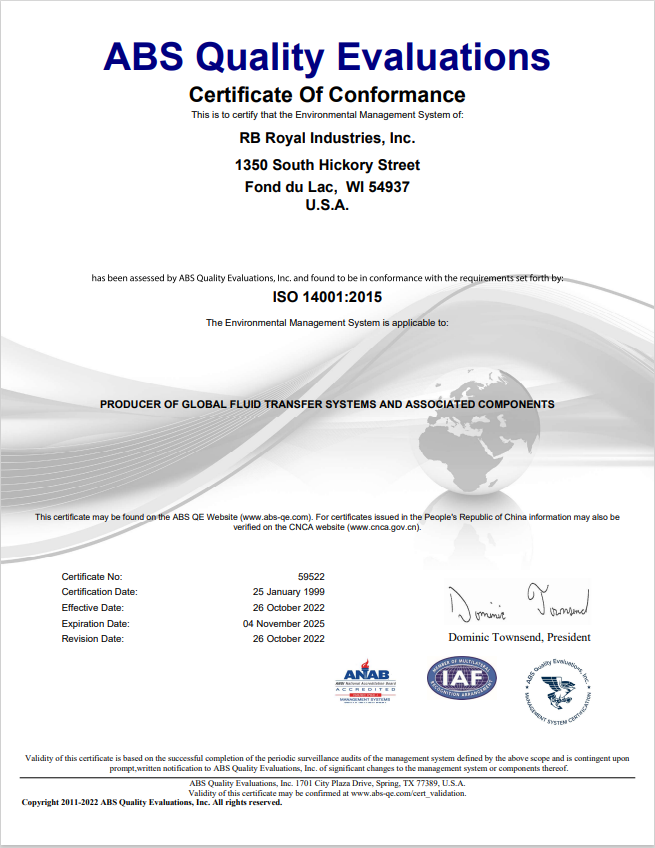

ISO 14001:2015 Certification:

Key additional quality processes include:

- Formal Production Part Approval (PPAP) Process

- Dimensional Layout

- Process Flow Diagrams

- FMEA (Failure Mode Effects Analysis)

- Control Plans

- Material / Performance Tests

- Part Submission Warrant (PSW)