The Benefits of Custom Dipsticks

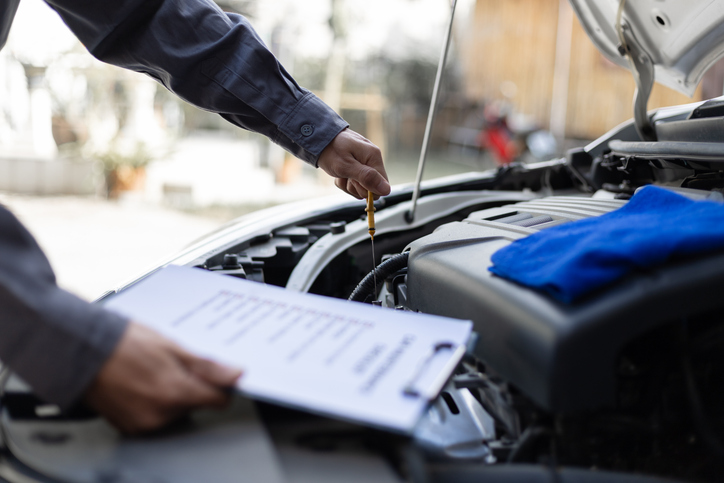

The dipstick is a critical engine component that measures and gauges oil levels, ensuring your vehicle is maintaining healthy levels.

How do custom dipsticks provide an advantage over basic dipsticks? They offer enhanced accuracy and reliability, and are made with better materials to ensure a longer service life.

RB Royal examines why manufacturers should use custom dipsticks and why making the switch is a cost-effective solution in the long run.

Enhanced Accuracy and Better Reliability

Custom dipsticks are built to enhance accuracy in checking oil levels, which leads to better vehicle reliability. Custom options are built to match exact customer specifications.

Higher Quality and Improved Durability

With a custom product, you should expect to receive a higher-quality product with improved durability compared to a stock option. Here’s how that’s achievable.

- Thorough quality checks are performed on custom dipsticks to ensure the product meets the specifications of both the manufacturer and the customer.

- Quality checks help ensure products are built to last longer and be more durable in a variety of conditions.

Application-Specific Custom Dipsticks

Not every dipstick is going to have the same application. The dipstick in your everyday automobile would not be appropriate to use in an excavator or dump truck. Be aware of the required specifications for your custom dipstick order. This includes industry, vehicle use, expected oil consumption, proper length of the dipstick, markings, and certifications.

Custom Components to Consider

Creating the custom dipstick is more than just bending, shaping, and adding a handle. Before the manufacturing process begins, keep these considerations in mind.

Locking or vented caps can be used to prevent leaks and pressure buildups. By preventing leaks and pressure buildups, your dipstick contributes to vehicle efficiency.

Different materials will be required for different applications as well; keep in mind the dipstick is crafted to withstand temperature changes, chemical abrasion, and mechanical stresses. Commonly used materials for custom dipsticks can include:

- Stainless steel is the most common choice. Stainless steel offers incredible durability and is also naturally corrosion-resistant.

- Carbon steel is another viable option and serves as a cost-effective solution. When treated with zinc or chrome plating, carbon steel also becomes corrosion-resistant.

- Steel cable is best suited for flexible dipsticks that have to navigate bends, and is most common in marine applications that feature tight spaces.

- Titanium is another commonly used material for specialty dipsticks. This material choice also offers corrosion resistance and is an excellent heat-resistant material as well.

The dipstick’s accompanying tube is another key component to factor in. Dipsticks and their tubes have to be an exact match to ensure proper oil levels and maintain accuracy when checking oil levels.

Connect With RB Royal Today For Your Custom Dipsticks

RB Royal is always expanding its capabilities to best serve the customer. As a custom dipsticks manufacturer, we know what it takes to raise the bar.

We make the switch from a stock dipstick to a custom solution easy. We’re an ISO 9001-certified company, and we can assure you that quality is central to everything we do. We only create and deliver the highest quality components for your every fluid transfer system need.

Ready for your custom dipsticks? Contact us today and see how RB Royal can best serve you.